Tromode is the only 'industrial' village on the Island.

The first Moore sailcloth works was started in Duke Street in 1790 by brothers James and Edward Moore with their father. As they needed a bleaching field they rented Ballabeg farm in Braddan on the other side of the river from Tromode. Following the death of their father in 1810 the brothers dissolved their partnership in 1814 - Edward started his business in the old corn mill across the river at Tromode whilst James moved back to Douglas starting his factory in Factory Lane (later Wellington Street) but in 1823 bought his brother's works after Edwards bankruptcy. James bought Cronkbourne (his invented name mixing Manx Cronk = Hill and English bourne = river) built Cronkbourne House and the works in which he was assisted by his son Willliam Fine Moore. On James' death in 1846 his estate passed by law to his eldest son Joseph Christian Moore who being unmarried and Archdeacon of Man, sold the business to his brother William Fine Moore.

The village was started in the 1840's by William Fine Moore to provide accommodation for the workers at his nearby Flax mill (making sailcloth etc.) along the river to the North of the village. He lived in Cronkbourne House a little to the south of the village along the river.

The plan, extracted from the 1868, 1:2500 plan shows the two lines of small terraced houses separated by a sward of grass. To the west the village green terminates in a schoolroom and chapel, to the east bounded by the river which originally provided power for the works. Four larger houses exist in the north-east - these were probably allocated to the skilled engineers needed for the machinery. Archibald Knox was born in Tromode whilst his father worked at Tromode.

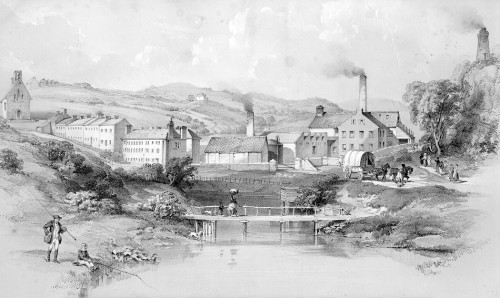

A lithograph was issued c.1850 showing a somewhat idealised view of the village (possibly the housing was intended to be two storey but they do look a little like a Scottish tenement).

The view is looking up the river to the factory from Cronkbourne House - the village is to the left.

The Manx Sun for 28 September 1850 gives a lengthy account of the factory in its early days.

The motive power is derived from an iron water-wheel . . . 19ft diameter and oft wide, the water is applied on the overshot principle. When the supply of water is plentiful the motion is entirely derived therefrom, and even in times of scarcity the water is by a peculiar contrivance, husbanded, as it were, so as to give an adequate supply for a few hours in the morning. . . . When the water fails to communicate the required motion recourse is had to a horizontal steam-engine of 16 inches cylinder and aft stroke. ... The wheel was made by John Rowan and Sons of Belfast.... The motion of this wheel . . . is conveyed by internal and external contrivances . . . to the rooms containing the different machines....We come now to the heckling. This operation is for the purpose of removing the tow or short fibre.... A quantity of the flax is arranged in a sort of case, and introduced at one end of the machine. Speedily the first operation is effected-that of getting rid of the coarser matter. In this state, the portion of the flax is passed, by the machine itself . . . into another division, and then to another, in each of which a different degree of fineness is produced, till, at last, every particle of extraneous matter is removed, and the whole of filaments arranged in distinct even and parallel fibres.... The heckling machine was manufactured by Samuel Lawson and Sons of Leeds, upon their patented principle The next process is accomplished by various drawing machines. The drawing is for the purpose of straightening the fibres. The first result of the drawing is what is called the sliver, a beautiful, glossy, ribbon-like arrangement of the fibres. The subsequent drawing is for equalising this sliver.... The product is then ready for roving.

The roving throws the sliver, thus arranged and equalized, into coarse thread, twisting it slightly, which thread is then ready for the spinners. The spinning is conducted in upper rooms, where there are 636 spindles . . . Here the coarse thread, derived from the roving, is spun and is afterwards reeled. The spinning and preparing machines were made by Samuel Lawson & Sons and Peter Fairbairne & Co of Leeds....

The yarn is also bleached on the premises. This department contains a plash-mill, washing reels, wringing hooks, and weft beating machine driven by a water-wheel. After bleaching process is accomplished, the yarn is in summer hung on poles in the neighbouring green to be dried, and in winter, this is effected by means of a stove. During the night time, and in rainy weather, the yarn is carried into a shed 150ft long and hung up there. The drying may now be supposed to be completed.

All is now ready for the weaving. This important part of the process takes place in a separate building . . . it is in reality one room. The roof consists of a number of divisions a peculiarity adopted for the due admission of light. The whole of the Northern aspect of each division is glazed . . . the power looms are by C. Parker of Dundee....

The following is an advert from 1923 Examiner Annual

THE above premises were formerly occupied in making Moore's Sail Cloths. Clucas's Laundry, Ltd., have made the works into a large Laundry and Brush making Factory. The Laundry is one of the largest and best equipped in the United Kingdom, and the Brush Factory is steadily growing into one of the largest Brush Factories. It is just doubling its turnover each year. This Laundry and Brush Factory is a great credit to the Island and speaks well for the ability and enterprise of the three partners, viz T. Clucas, S. Clucas, and W. Callow. This is the only Laundry Co in the British Isles which provides houses for its employees. The Company owns the whole village of Tromode, and their employees occupy all the houses. The village is lighted by electricity, and is worth a visit any evening to see the decided improvement of Lighting by Electricity instead of gas. The electric current for both village and works is generated by Water Turbines, which were recently added to the laundry plant to replace the water wheel formerly used by the Sail Cloth Works.

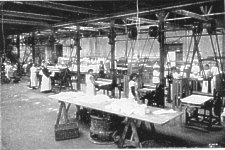

Interior of Clucas's Laundry c. 1913

(from NMP Manx Year Book 1914)

The sail cloth works closed in 1905 ; the site was taken over for many years as Clucas's laundry and brush factory but in the 1990's became a somewhat rundown industrial site - a new housing estate has been built to the east and the village itself, initially threatened with destruction seems to have been saved. The south row of houses have had extensions to the rear - following extensive renovation both rows have kept their facades but the interiors have been modernised..

|

|

View of south row of houses - after recent restoration |

|

The schoolroom and hall looking west - built to a design of Ewan Christian. There was originally a bell turret on the gable wall. |

|

|

|

The chapel entrance looking east - as the village is built on a hill this entrance is into the upper floor of the schoolroom. |

T.A.Bawden, L.S. Garrad, et al The Industrial Archaeology of the Isle of Man Newton Abbot: David & Charles 1972 (ISBN 0-7153-5440-X)

Cronkbourne Village IoMFHS vol X no3 p p68-70

[P Kelly] Taking the Wind out of their Sails IoM Vic Soc Newsletter #50 pp16/8 May 1998

|

|

||

|

Any comments, errors or omissions

gratefully received The

Editor |

||